Roll Forming

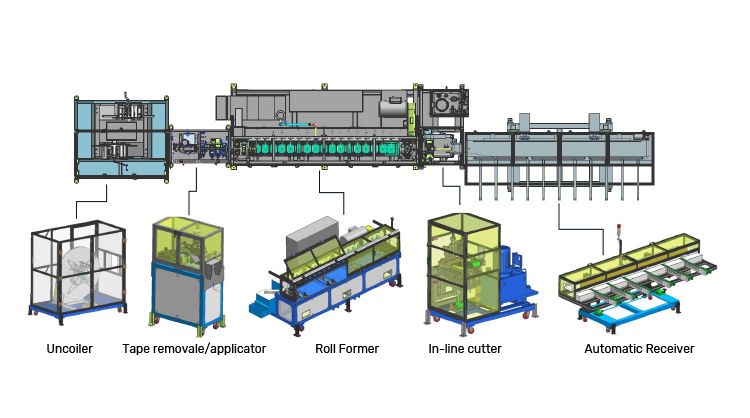

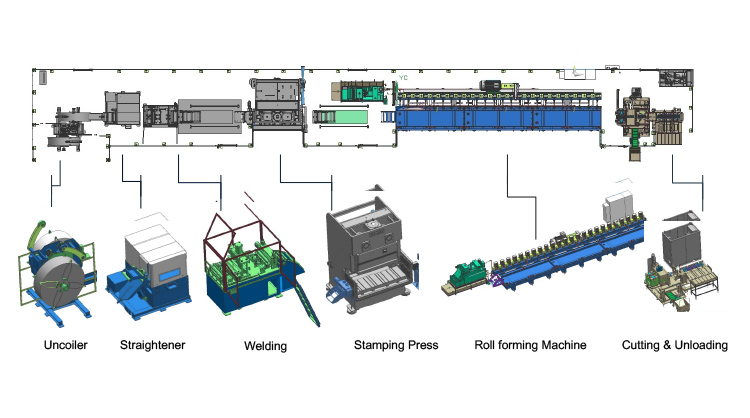

We develop roll forming machines and tools for decorative parts (high gloss) and structural parts, as well as related equipment such as decoiler, puller, inline notch, cutter, strip applicator, inline welder, bending device and more.

In addition to turnkey solutions, we can also supply the tooling for your existing machine.

Rollformed Products

High Gloss Appearance

Roof rail, Roof ditch molding, Glass run trims, Outer waist belt trims

Structural Parts

Door frames, B Pillar Appliques, Bumper Beams, Cross Member, EV Battery Tray Profiles

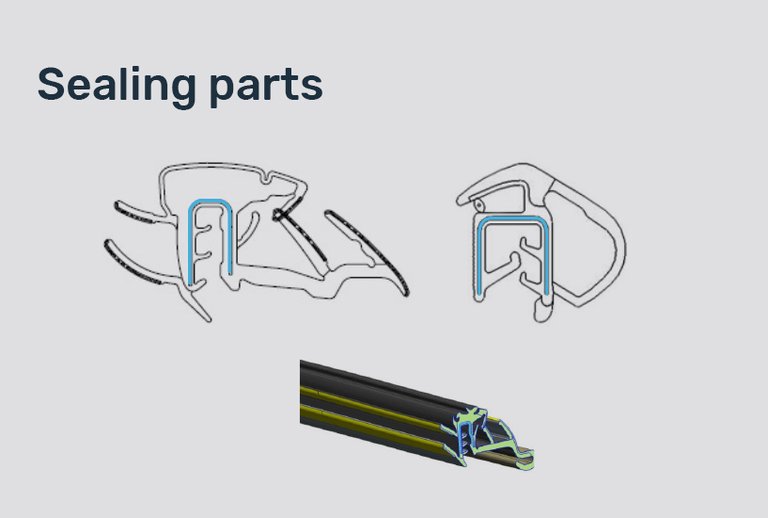

Sealing Parts

Extrusion carrier (pre-form and post-form)

Manufacturing Equipment

Made by FSM

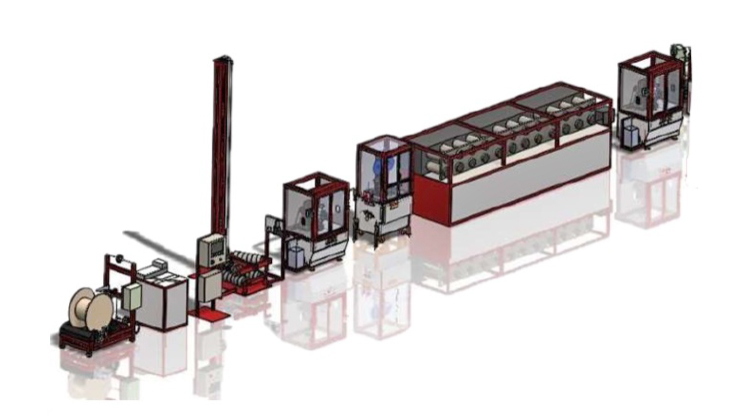

Roll forming Equipment

Rolling stands: max. 50 sets

max. Roll diameter: 350 mm

max Speed: 40 m/min

Tooling: quick changeable

Material we can process: steel, stainless steel, high strength steel, aluminum

Roll forming Line with related Equipment for GM E2LB /9BYC /CN202S exterior Trims

Speed: 18m/min

Material we can process: stainless steel, aluminum

Qty of products: 5

Roll forming Line High strength Steel Ford Transit V710 Cross Member & Bumper Beam Equipment

Speed: 12 m/min

Material we can process: WSS-M1A368-A84

Qty of products: 10