Automation & Integration

Automation mainly means an increase in productivity and efficiency.

We at FSM develop and build fully automated manufacturing machines for your production. It is important to us to adapt the machine to your needs in order to achieve the optimum.

Our strength is the development of turnkey production equipment, we integrate different processes such as sawing, milling, punching, stretch bending, marking and measuring but also the assembly of different parts and standard components is included in our portfolio.

From loading of parts into the machine up to the packaging of the finished product, you can get everything from one source.

Automation is our passion, quality is our highest priority.

MANUFACTURING EQUIPMENT

MADE BY FSM

KEY DATA

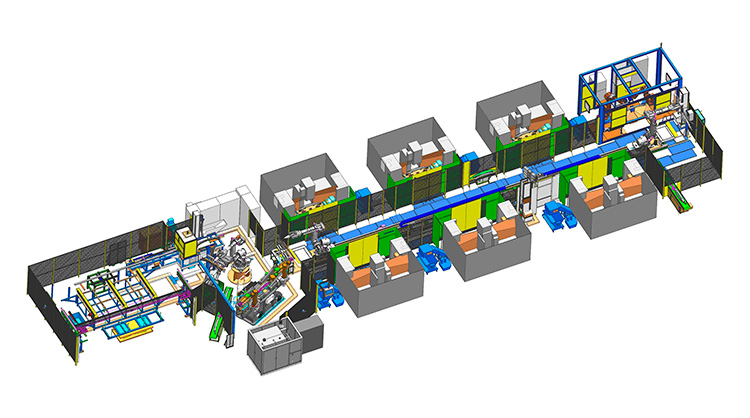

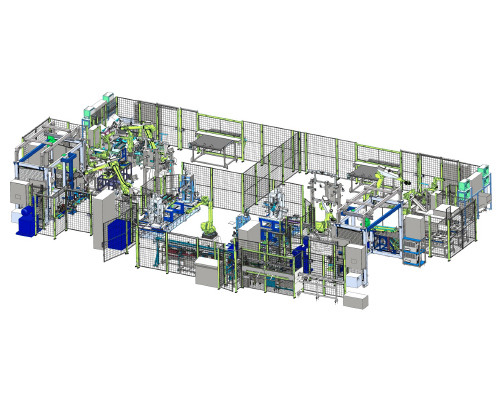

ROOF RAIL MANUFACTURING LINE

Project: different Audi-, VW-, Daimler-Projects

integrated processes: automatic profile loading, stretch bending, milling and drilling, deburring, measurement station, laser marking, automatic profile unloading

Features: automatic milling tooling changeover, flexible for different products, quick tooling changeover, extendable with 3 milling cells for high volume

KEY DATA

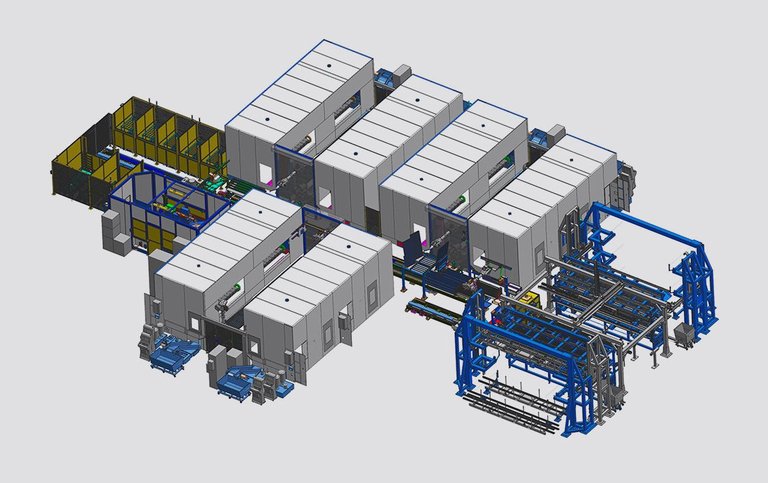

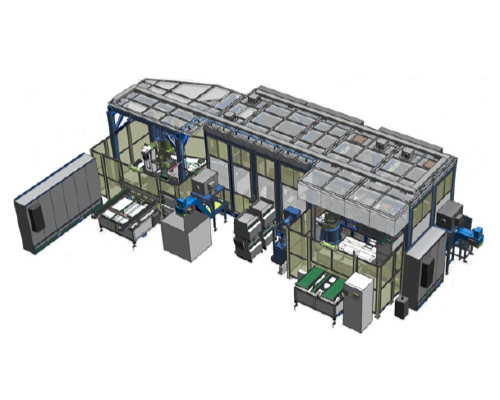

EV BATTERY TRAY SINGLE PART MANUFACTURING LINE

Project: BMW iX (i20)

Integrated processes: automatic profile loading with profile section and hardness control, sawing to length, milling and drilling, deburring, laser marking, automatic profile unloading

Features: mixed production, maintenance possible without full production stopp, tooling changeover without production stopp, profile loading and unloading without production stop

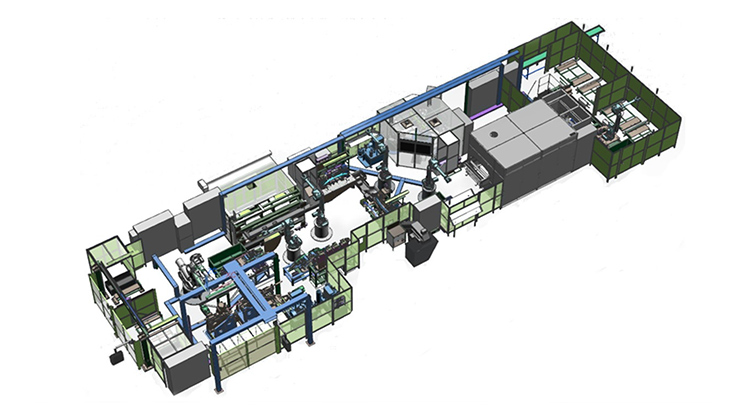

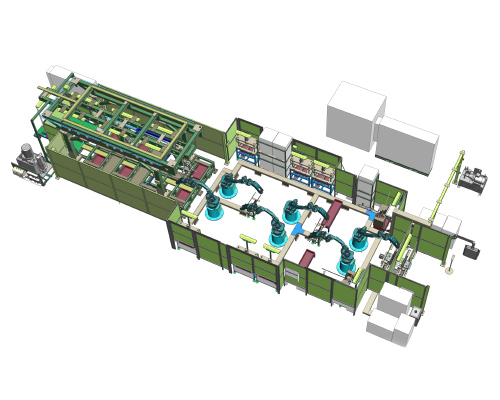

BUMPER BEAM PRODUCTION LINE

Project: BMW G2X

Integrated processes: automatic profile loading with hardness, length and section control, stretch bending and press bending, sawing and milling, notching, deburring, washing, laser marking, automatic profile unloading

Features: flexible for different products, quick tooling changeover

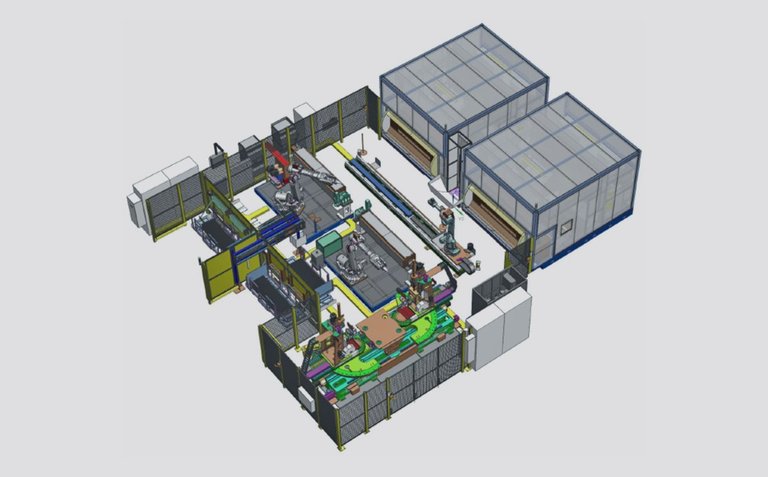

BUMPER BEAM PRODUCTION LINE

Project: Tesla Model Y

Integrated processes: automatic profile loading, sawing with hardness, length and section control, stretch bending, milling, notching, deburring, laser marking, automatic profile unloading

Features: flexible for different products, quick tooling changeover

ROOF DITCH MOLDING PRODUCTION LINE

Project: different Daimler Projects

Integrated processes: stretch bending, cutting & nocthing, assembly of end caps, spacers and square flaps, length control, laser marking

Features: LH & RH parts produced simultaneously, flexible for different products, quick tooling changeover, inline with the extrusion

TRIM MANUFACTURING

LINE

Project: different Audi-, VW-, Daimler-Projects

Integrated processes: stretch bending, robot milling, end forming, 5-aixs milling, deburring, laser marking

Features: LH & RH parts produced simultaneously, flexible for different products, quick tooling changeover

STAINLESS STEEL TRIM PRODUCTION LINE

Project: different Chrysler- and GM-Projects

Integrated processes: laser cutting, notching, end cap forming, deburring, laser marking

Features: flexible for different products, quick tooling changeover