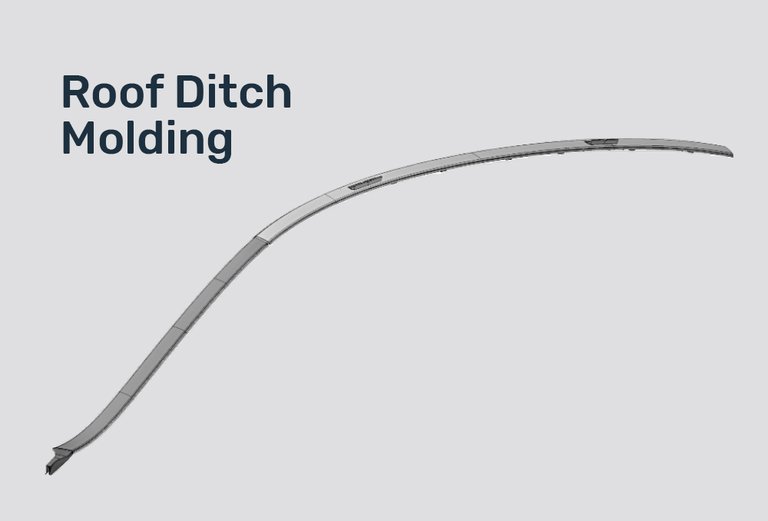

ROOF RAIL &

ROOF DITCH MOLDING

Are you looking for a suitable production process for aluminum roof rails or roof ditch molding? We have the right solution for your production.

Our portfolio ranges from single or interlinked machines with manual part handling up to fully automated production lines.

Manufacturing Equipment

made by FSM

KEY DATA

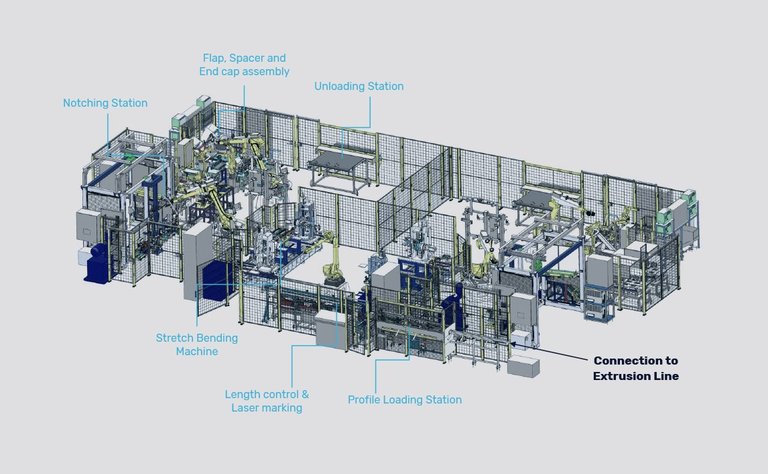

Project: Daimler AG 294 / 296

Cycle time: 17 seconds/set (LH and RH part)

Integrated process/technologies: auto-loading & unloading of parts, stretch bending, notching, spacer / flap and end cap assembly, laser marking

Autonomy time: 2 - 3 hours

Product changeover: < 15 min

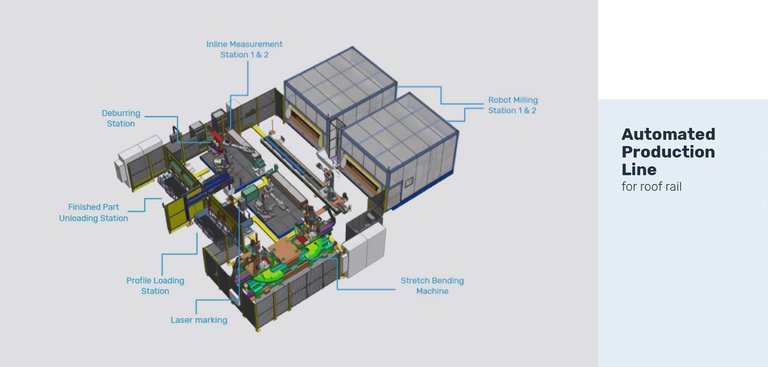

Project: VW Passat (B8)

Cycle time: 25 seconds/part

Integrated process/technologies: auto-loading & unloading of parts, stretch bending, Robot milling, deburring, laser marking

Autonomy time: up to for 2 hours

Product changeover: < 30 min

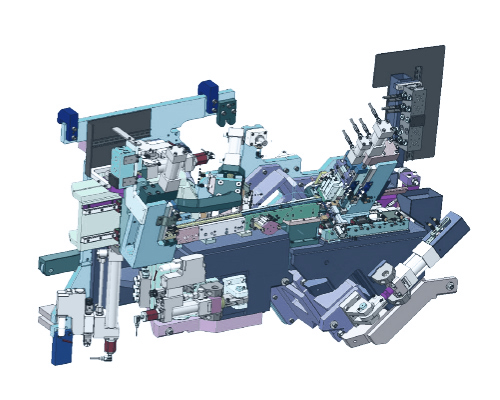

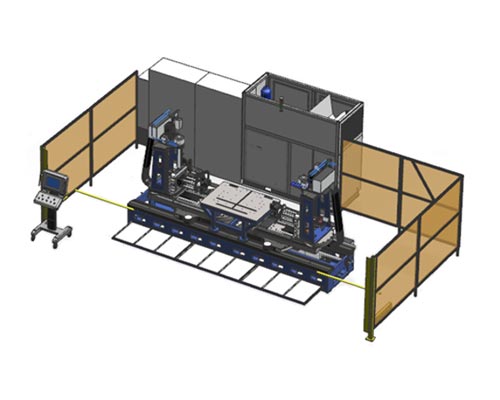

Stretch Bending Machine

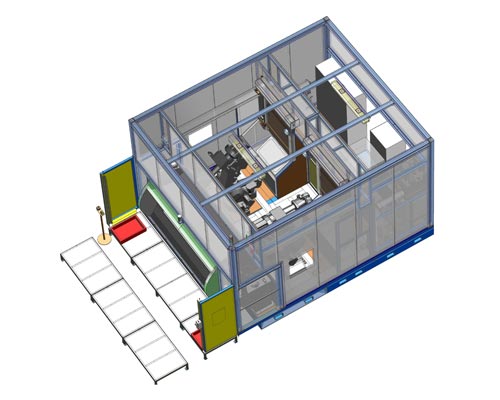

Milling machine

ROOF DITCH MOLDING – WATER DEFLECTOR BENDING TOOLING