The future

belongs to electro mobility.

This technology ensures that eco-friendly, quiet and efficient vehicles will be on our roads. In addition to the actual electric motor, the battery is a key element in the electric vehicle and at the same time a sensitive and expensive component.

The battery must be crash-proof and corrosion-resistant, electromagnetically protected and cooled. We at FSM develop equipment for the production of battery housings and we are specialized in several areas. We have successfully realised projects for Porsche Taycan (J1), BMW iX (i20) and Daimler EVA 1.5 / 2.

Question or request?

Please feel free to contact us.

Manufacturing Equipment

made by FSM

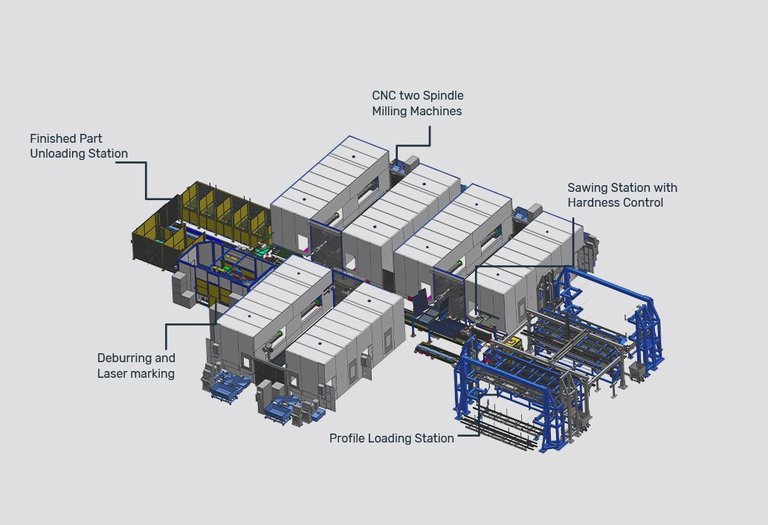

KEY DATA

Project: BMW iX (i20)

Cycle time: 90 seconds / car set

Integrated process/technologies: auto-loading & unloading of parts, hardness check, sawing, milling & drilling, deburring, laser marking

Autonomy time: up to 4 hours

Features: Automatic tool changeover

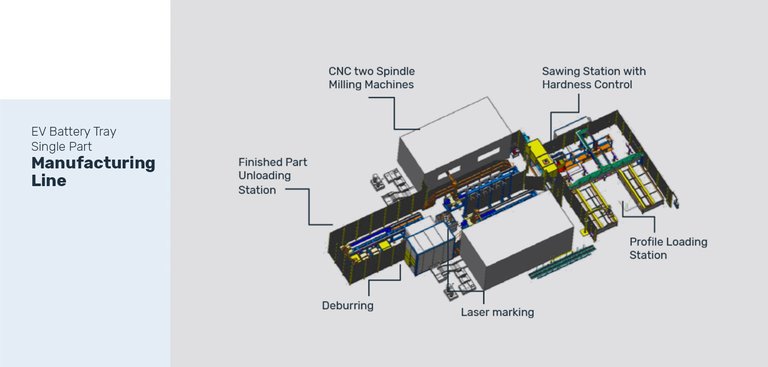

EV BATTERY TRAY SINGLE PART MANUFACTURING LINE

Project: BMW iX (i20)

Cycle time: 290 seconds / car set

Integrated process/technologies: auto-loading & unloading of parts, hardness check, sawing, milling & drilling, deburring, laser marking

Autonomy time: up to 4 hours

Features: Automatic tool changeover

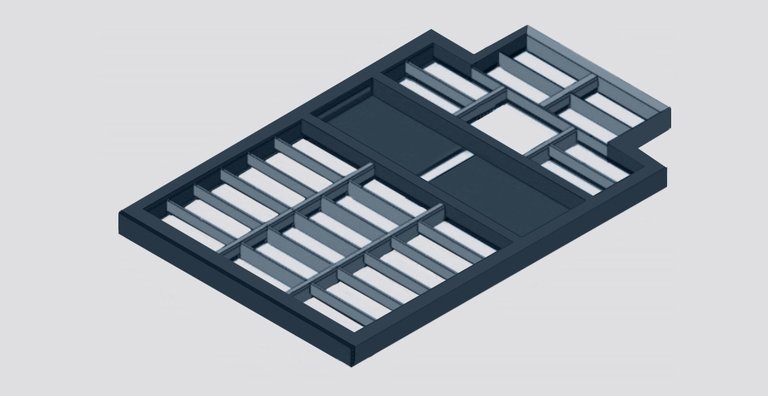

Milling machine

for battrery tray profile manufacturing

Features:

- Machine tables: 2

- Number of spindles: 2

- Spindle brand: HSD, Power: 25kW, Rotation Speed: 24.000 U/min-1

- Application: aluminum profile machining, manual or automatic loading of parts possible