Your way to a

turnkey solution

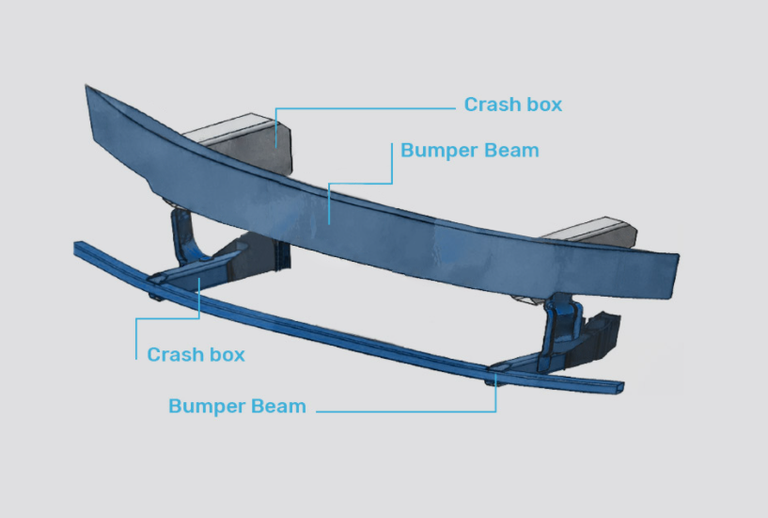

Different technologies and manufacturing steps are required to produce crash management systems. Whether stretch bending, cutting, milling, sawing or the assembly of standard parts, we at FSM integrate the processes into a manufacturing line and offer our customers turnkey solutions to produce crash boxes and bumper beams.

In the past years we have successfully completed projects for BMW, Daimler, Tesla and Ford, so we are familiar with the highest quality standards and the most diverse designs.

Question or request? Please feel free to contact us.

Manufacturing Equipment

made by FSM

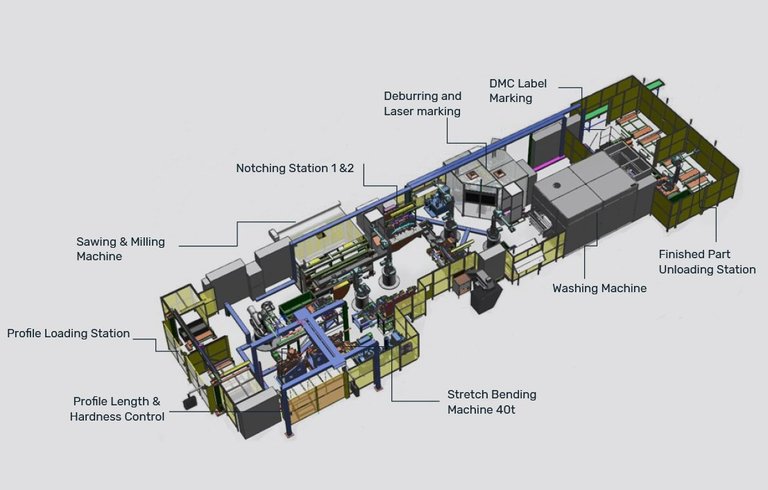

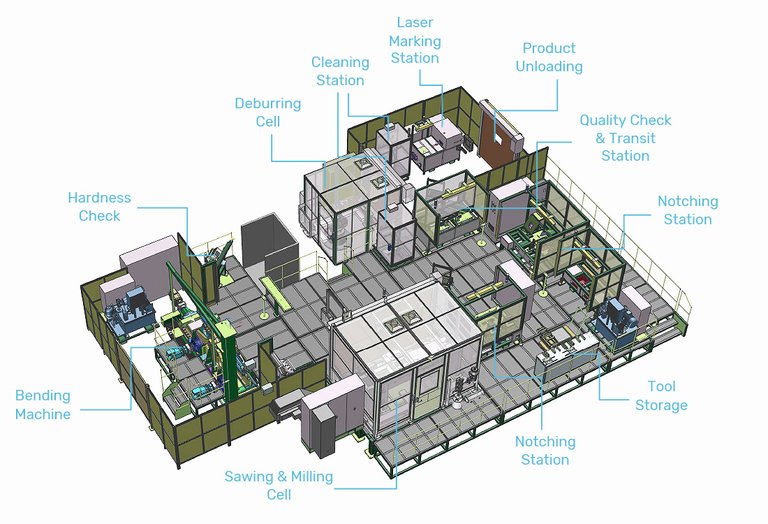

KEY DATA

Project: BMWG2X (3 Series)

Cycle time: < 25 seconds/part for automatic production lines (1x Operator)

Integrated process/technologies: eddy current test (T4,T5,T6), stretch bending, sawing, milling, brushing, notching, drilling, laser marking, camera measuring, robot application, auto-loading & unloading of parts

Autonomy time: up to for 4 hours after Profile loading

Tooling Changeover time (Product changeover): < 30 min

QTY Products manufactured on this line: 10

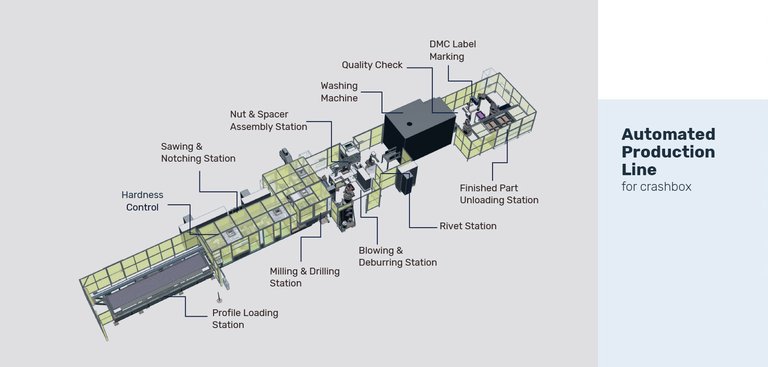

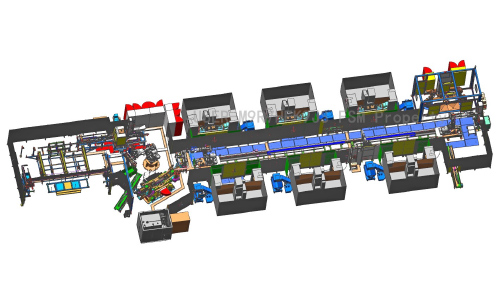

KEY DATA

Project: BMWG2X (3 Series)

Cycle time: 20-24 seconds/part for automatic production lines

Integrated process/technologies: eddy current test (T4,T5,T6), auto-loading & unloading of parts , sawing, milling, brushing, notching, standard components assembly, washing, laser marking, camera measuring

Autonomy time: up to for 4 hours

Product changeover: < 10 min

QTY Products manufactured on this line: 6

MANUAL PRODUCTION LINE

MANUAL HANDLING BUMPER BEAM LINE

Project: BMWG2X (3 Series)

Cycle time: < 55 seconds/part (4 Operators)

Integrated process/technologies: eddy current test (T4,T5,T6), stretch bending, sawing, milling, brushing, notching, drilling, laser marking, mechanical and laser sensor for quality control

Tooling Changeover time (Product changeover): < 15 min

QTY Products manufactured on this line: 10

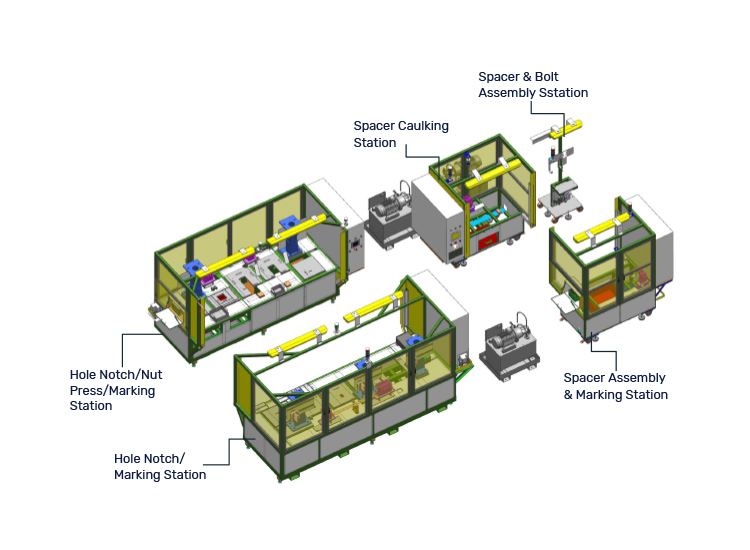

Manual handling crash box line

Project: BMWG2X (3 Series)

Cycle time: 25 - 40 seconds / part with 3 operators

Integrated process / technologies: eddy current test (T4,T5,T6), sawing, notching, stamping, standard component assembly, part marking

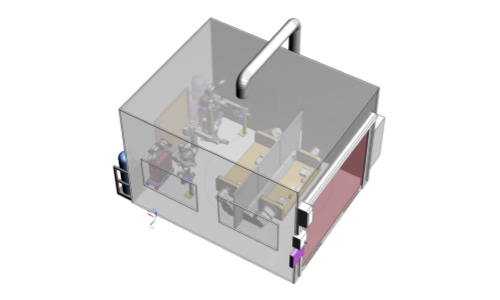

WELDING OF

CRASH MANAGEMENT

SYSTEM

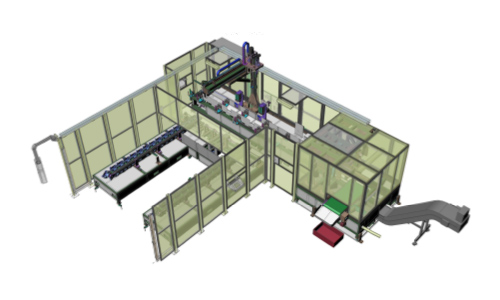

Automated

bumper beam

production line

Sawing machine

for aluminium

profiles

Angle Sawing

Machine For Aluminium Profiles