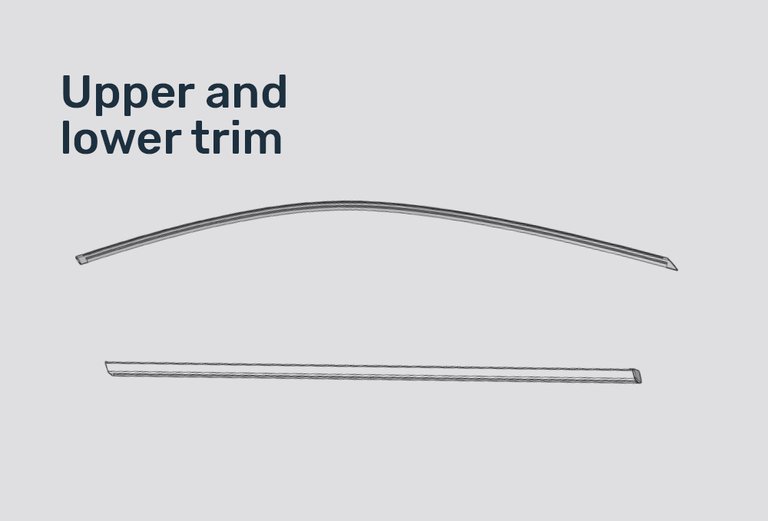

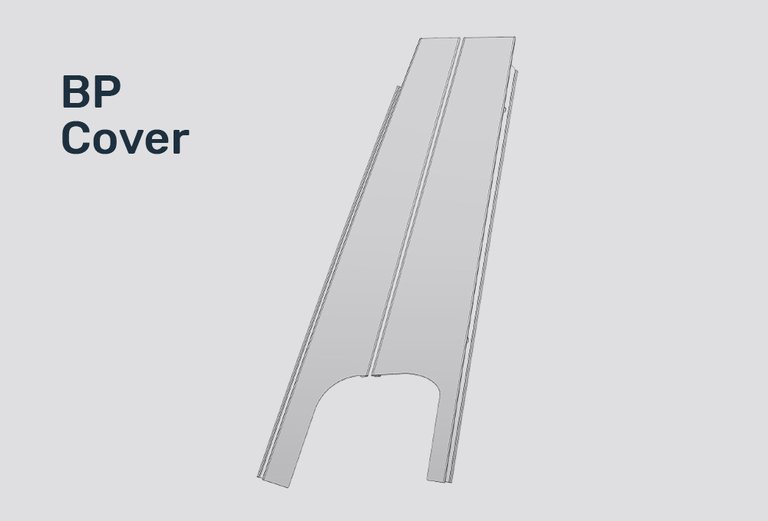

EXTERIOR TRIMS

In the production of aluminum or stainless-steel trim strips for the automotive industry, the surface quality of the product plays a decisive role.

Based on years of experience and countless projects, we know these requirements exactly and offer you the complete portfolio for the production of these components from mechanical processing to polishing, find out now.

Manufacturing Equipment

made by FSM

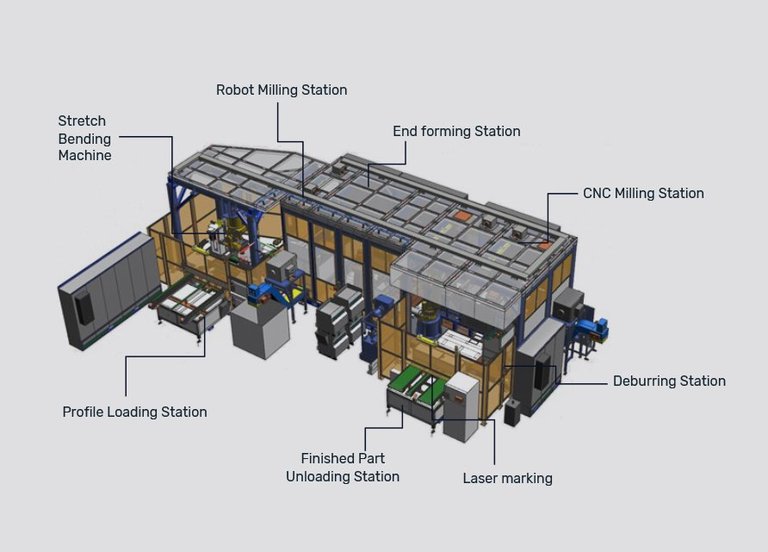

KEY DATA

Project: Audi AU326 (Q3)

Cycle time: 20-25 seconds/set

Integrated process/technologies: auto-loading & unloading of parts, stretch bending, notching, end forming (End caps), Robot milling, deburring, laser marking

Product changeover: < 30min

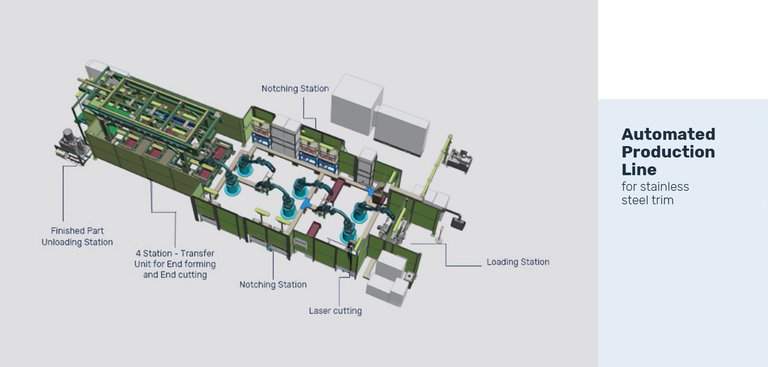

Project: BWM F48 & F49 OWB

Cycle time: 25-35 seconds/set (LH and RH part)

Integrated process/technologies: auto-loading & unloading of parts, stretch bending, notching, end forming (End caps), laser cutting

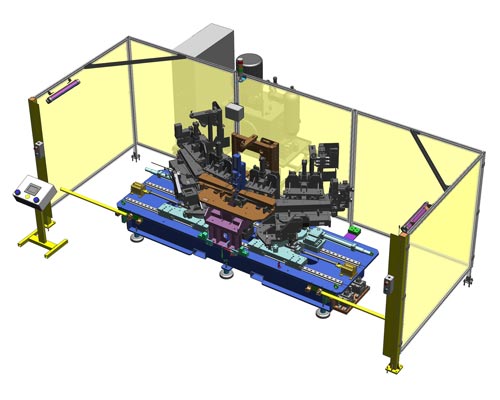

Bending Machine

for trims

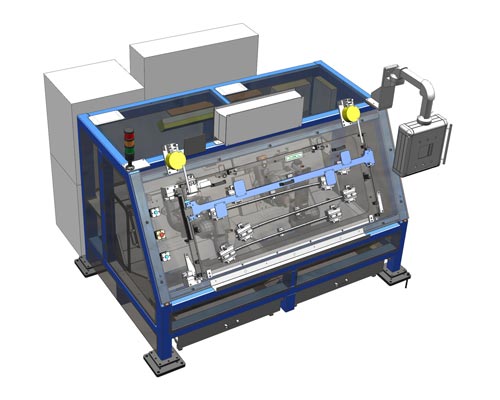

Milling machine

for trims

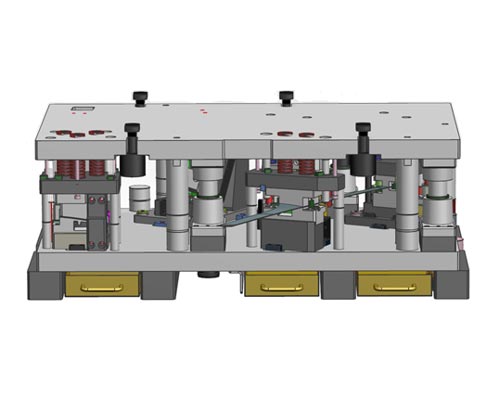

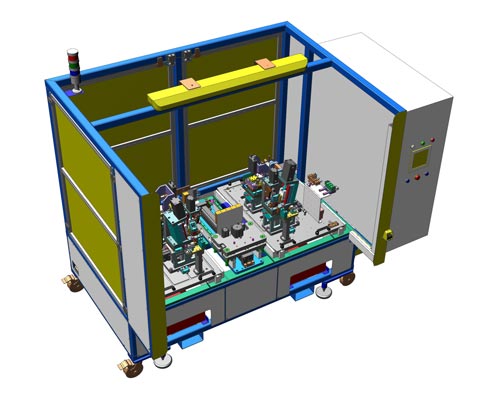

Notching & endforming machine for Trims

Stamping tooling quarterlight