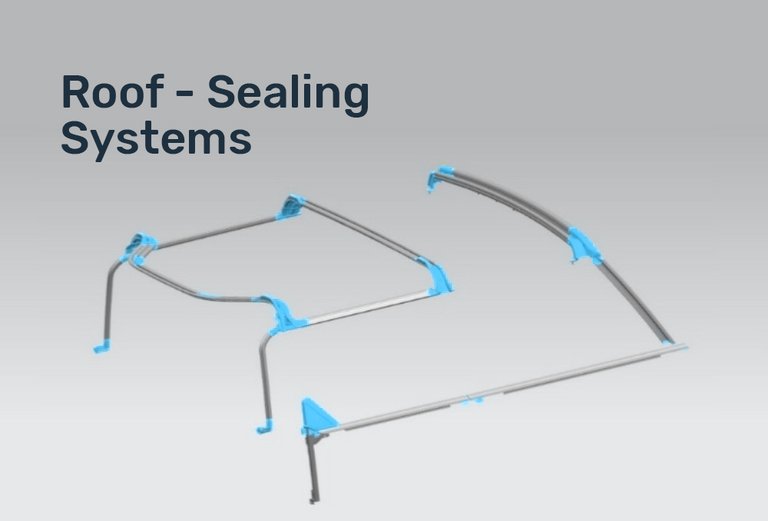

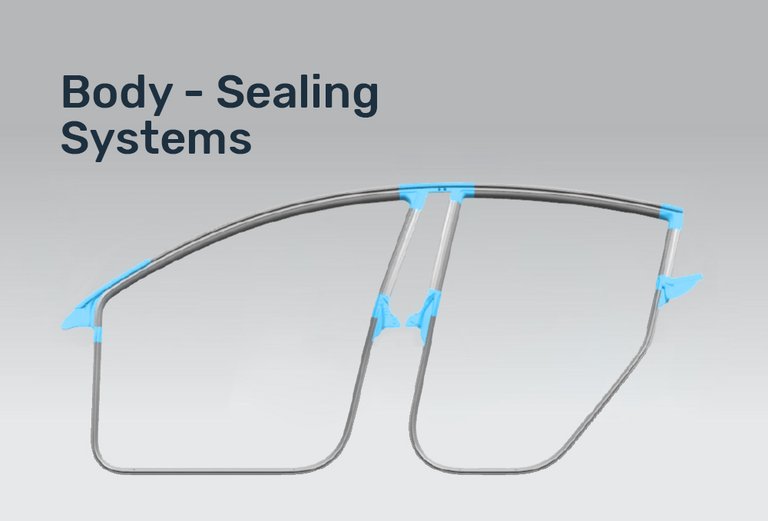

Automotive sealing parts

Years of experience and countless projects have made us one of the leading equipment suppliers for automotive sealing systems. We offer turnkey solutions for your production. Our portfolio ranges from roll forming systems and tools for profile carriers to punching equipment up to complex EPDM and TPE injection molds. We support our customers with feasibility analyses before the actual project start, the production of sample parts on our in-house equipment is fast and uncomplicated possible. Find out now - everything from a single source – that´s FSM.

Our Products

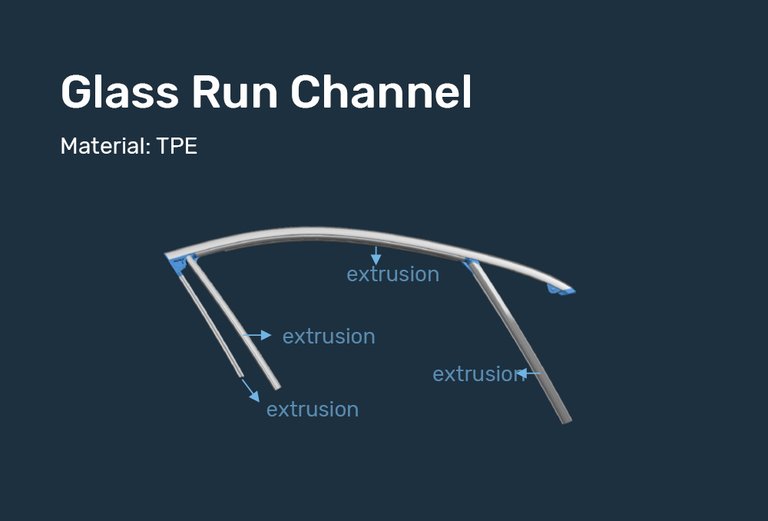

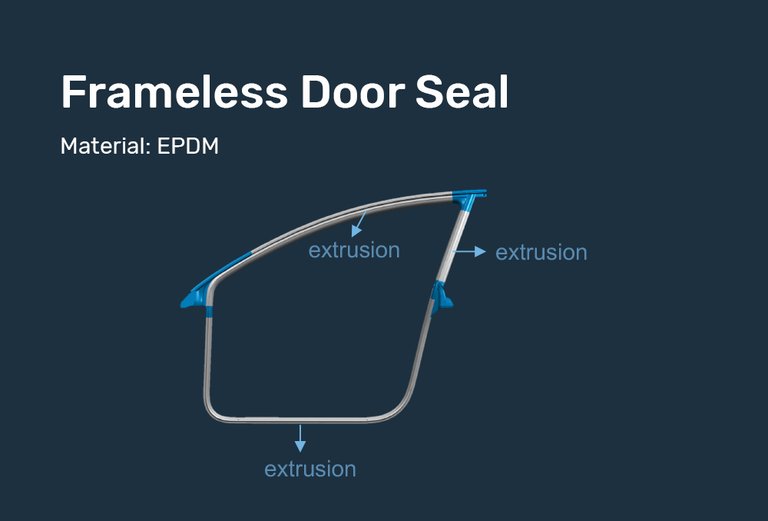

TECHNOLOGIES

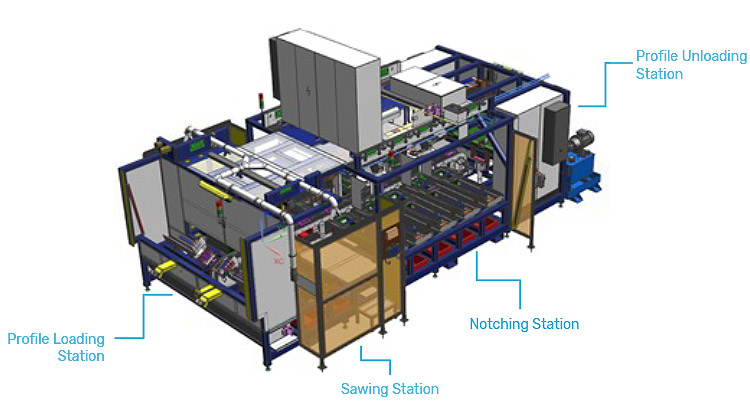

SEALING NOTCHING TRANSFER MACHINE

Profiles which can be processed: Header, OWB, IWB

Cycle time: 15-25 seconds/part

Integrated process/technologies: Profile sawing to length, Profile notching

Available Options: Auto-loading & unloading, bending, drilling, measuring, marking

Product changeover: 5 - 20min

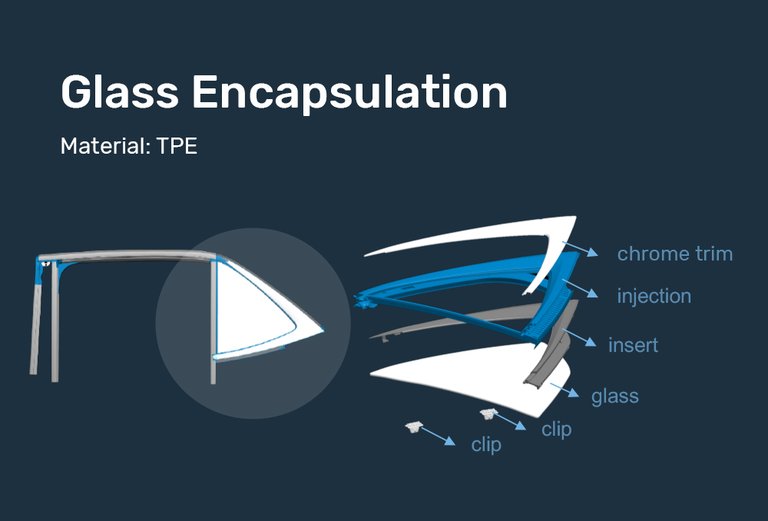

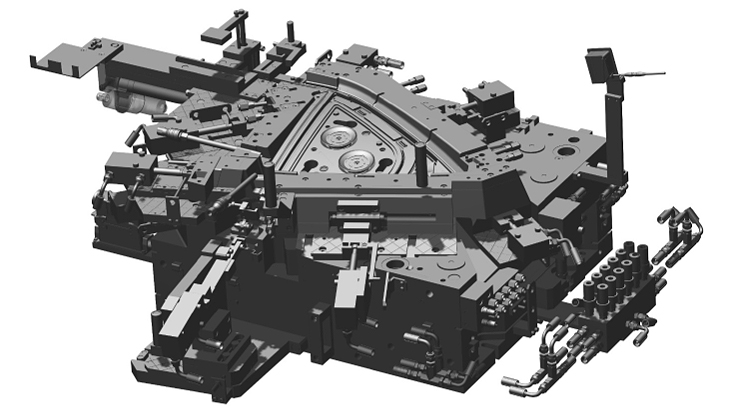

TPE GLASS ENCAPSULATION MOLD

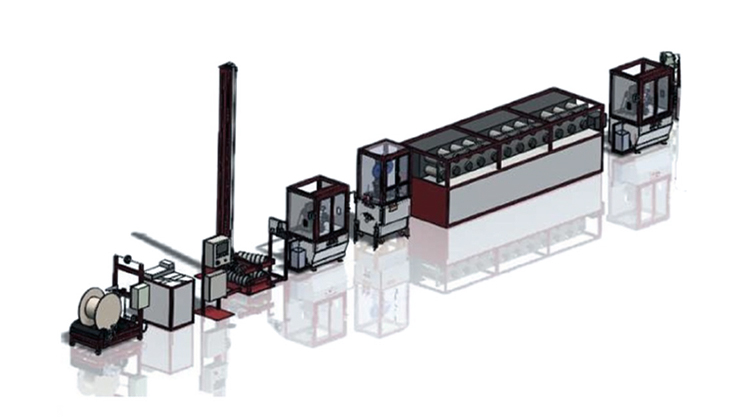

SEALING EXTRUSION CARRIER ROLLFORMING LINE

Rolling Stands: max. 50 sets

Max Roll Diameter: 350 mm

Max Speed: 40 m/min

Tooling: quick changeable

Material we can process: Steel, Stainless steel, High strength steel, Aluminum